HSS-Drilling tools are a cost effective alternative to solve a machining task. They are manufactured from a High Speed Steel (=HSS). Characteristical traits are a high wear-resistance, a good durability and a high tempering resistance.

Our norm program covers standardized applications. Subland drills are manufactured according to the valid DIN standard, short step drills, step drills for center drills and NC-center drills correspond to our company standard.

The standard articles shown in our high-speed steel program are generally available on short notice.

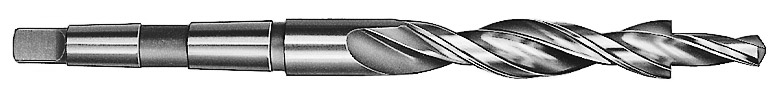

DIN 8374, DIN 8378

for through holes/

core drill holes,

countersink angle 90°

fine, medium

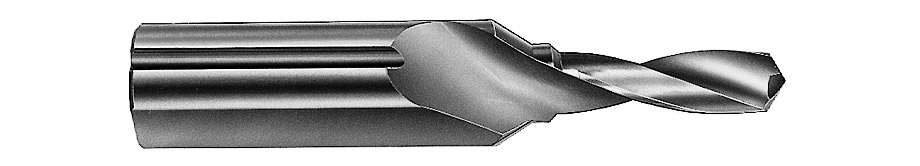

DIN 8376, Factory Standard

for through holes,

countersink angle 180°

fine, medium

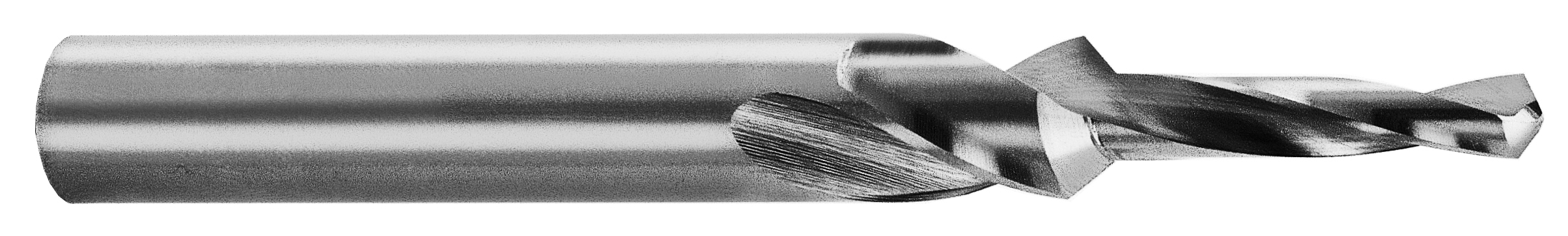

DIN 8375, DIN 8379

for through holes/

core drill holes,

countersink angle 90°

fine, medium

DIN 8377, Factory Standard

for through holes,

countersink angle 180°

fine, medium

Factory Standard

step drill for threaded bores

according to DIN 332, page 2

Shape D (60°) – as pictured

Shape DR (radius)

Shape DS

(with countersink protection),

on request

cylindrical

Factory Standard

step drill for threaded bores

according to DIN 332, page 2

Shape D (60°) – as pictured

Shape DR (radius)

Shape DS

(with countersink protection),

on request

conical

Factory Standard

for through hole according to DIN EN 20273, for countersink 90°

fine, medium

steamed (pic.)

or TiAlN-coated

Factory Standard

for through hole according to DIN EN 20273, for countersink 180° according to DIN 974-1, for screws according to DIN 6912, DIN 7513, DIN 7984

medium

dsteamed

or TiAlN-coated (pic.)

Factory Standard

for threaded bore according to DIN 336, for free countersink 90° according to DIN EN 20273

medium

steamed

or TiAlN-coated (pic.)

Factory Standard

for drilling and countersink in a single process, for through holes for screws and countersink for screw heads

medium

blank

Factory Standard

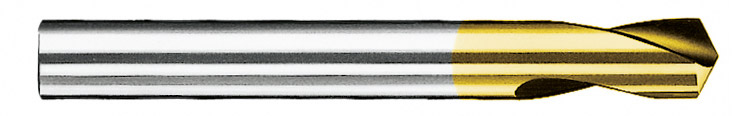

for spot drilling

60°, 90°, 120° (pic.), 142°

cylindrical, with driving surface

(up to Ø 6 mm),

surface blank

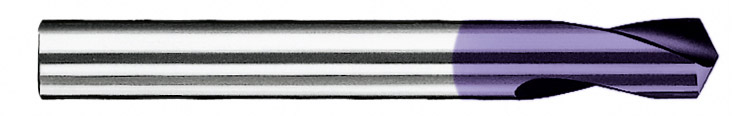

Factory Standard

for spot drilling

90°, 120° (pic.), 142°, 60°

cylindrical, with driving surface

(up to Ø 6 mm),

surface TiAlN-coated

Factory Standard

for spot drilling

60°, 90°, 120° (pic.), 142°

cylindrical, with driving surface

(up to Ø 6 mm),

surface FUTURA coated

Factory Standard

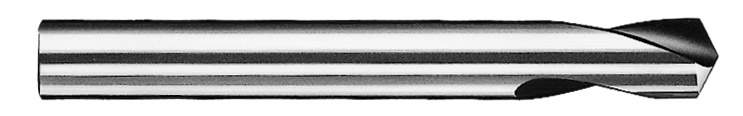

for spot drilling 120°

conical point angle 120°

surface blank

Factory Standard

for spot drilling 90°

conical point angle 90°

surface blank