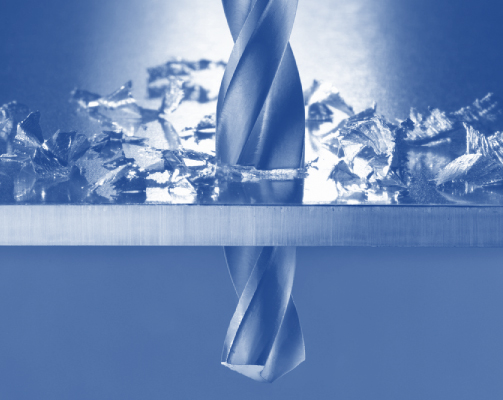

Established more than 60 years ago, Volz Drilling Tools GmbH is still an owner-managed family business with 20 high-qualified and motivated employees. Our core competence is the production of high-quality drilling tools made of high speed steel (HSS) and solid carbide. Besides our standard product program we also manufacture tools, which are designed for individual usage for many different industries. Modern manufacturing engineering, high-end materials and a consistent quality assurance guarantee a continuous high standard of our products and allows us to be flexible in regard of the needs of our customers. Slight configurations, decades of experience and our own demand in regard of quality and precision make us a perfect partner in the area of drilling tools.

In order to ensure the outstanding quality and the strict process standards

at Volz Drilling Tools, we regularly conduct comprehensive material

and hardness tests.

Each individual production stage up to the delivery is subject to a steady

control. Strict inspection procedures and complete traceability ensure

the high manufacturing standard on which our customers can rely on.

Since 2007 Volz Drilling Tools GmbH is holder of the quality certificate

DIN ISO 9001.

at the highest level is the ultimate ambition of our company policy.

Don‘t hesitate to contact us by telephone (0049 7461 8157) or write an E-Mail.

Your requests will be handled as soon as possible. Be sure to get an answer soon.

| DESCRIPTION | APPLICATION | |

|---|---|---|

|

Standard chip flute | for steel processing type N |

|

Open chip flute | for brass type H |

|

Reversed back | for aluminium processing type W |

|

Double margin | for spot drilling and drilling out, exact guidance in drilling bush using 4 chamfers |

|

Subland drill | |

|

Subland reamer | for simultaneous drilling and reaming |

|

Counter sink | |

|

Subland countersink |

| SHAPE | APPLICATION | |

|---|---|---|

|

Cone polished section with point-thinning cross-edge | for steel processing type N |

|

Cone polished section with point-thinning cross-edge and adjusted major cutting edge | for durable materials with point angle 118° for high-strength materials > 1000N/mm² |

|

Split point | for forged materials |

|

Point grind for cast iron | for GG, GTS, GTW and drills with non-straight exit field |

|

Center point | for flexible material and thin workpieces |

More information is shown in the DIN standard 1412 at the respectively valid version (Source: Beuth-Verlag).

In practice, further point grind versions have been developed. Please contact us if you are interested in special polished sections for your tools.

The tool application categories, so far referred to as type of tool, marks the usability of the tool for the economical cut of various material groups and identifies the cutting edge geometry of the tools.

| RANGE OF APPLICATION | |

|---|---|

| N | Chipping of materials with standard stability and hardness |

| H | Chipping of hard, hard and tough, and/or short-chipping materials |

| W | Chipping of flexible, durable and/or long-chipping materials |

More information is shown in the DIN standard 1836 at the respectively valid version (Source: Beuth-Verlag).

| DIN-STANDARD | DESCRIPTION |

|---|---|

| DIN 1809 | Tools with cylindrical shank and driving pin |

| DIN 228 | Tools with taper shank, form B with tang |

| DIN 1835/FORM B | Tools with cylindrical shank, form B, with lateral driving surface |

| DIN 1835/FORM E | Tools with cylindrical shank, form E, with inclined clamping surface |

| DIN 6535/FORM HB | Tools with cylindrical shank, form HB, with lateral driving surface |

| DIN 6535/FORM HE | Tools with cylindrical shank, form HE, with inclined clamping surface |

In many applications, hard coatings offer important advantages such as higher durability, toughness, heat resistance and better gliding properties.

Due to our collaboration with well-known German coating companies, we offer you the possibility to coat your drilling tools with the hard coatings

TiN, TiAlN or TiCN.

| COATING | CHARACTERISTICS | APPLICATION |

|---|---|---|

| TIN | Versatile standard coating | steel processing, plastic injection |

| TICN | heat resistance, oxidation resistance | for HSS and solid carbide tools with high thermal strain |

| FUTURA/TiAIN | high hardness, good durability | for tools with high mechanical strain |

| DESCRIPTION | |||

|---|---|---|---|

| COATING | TIN | TICHN | FUTURA/TiAIN |

| Micro-hardness HV 0,05 | 2300 | 3000 | 3000 |

| Friction against steel (dry) | 0,4 | 0,4 | 0,4 |

| Coating thickness | 1-4 µm | 1-4 µm | 1-5 µm |

| Max. application temperature | 600°C | 400°C | 500°C |

| Coating color | gold-gelb | blau-grau | violett-grau |

| Layer structure | Monolayer | mehrlagig | Multilayer |